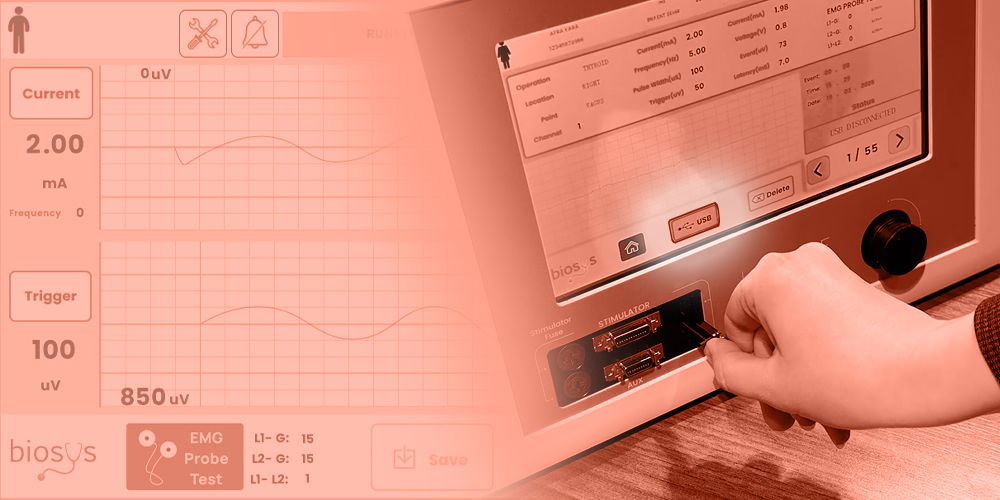

The Bioscope by Biosys system requires various consumables to function effectively during ENT, hand, and facial surgeries. Here’s how to properly use, maintain, and replace these consumables, followed by a comparison with brand A and brand B.

How to Properly Use, Maintain, and Replace Bioscope Consumables

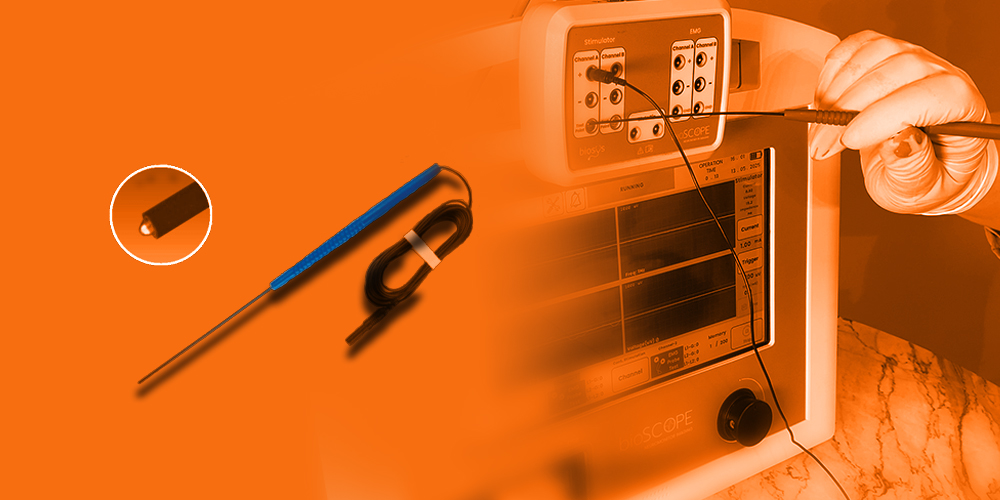

1. Needle Electrodes (EMG Monitoring)

- Use:

- Insert needle electrodes into the target muscle or nerve area to record EMG signals.

- Ensure proper placement to avoid inaccurate readings or tissue damage.

- Maintenance:

- None; these are single-use only.

- Replacement:

- Discard after each surgery following biohazard disposal protocols.

- Cost per electrode: $5 – $20.

2. Adhesive Surface Electrodes (EMG, SSEP Monitoring)

- Use:

- Apply a thin layer of conductive gel or paste to improve signal conductivity.

- Place electrodes over the skin where nerve signals are to be detected (e.g., vocal cords or facial nerves).

- Secure electrodes properly to prevent shifting during surgery.

- Maintenance:

- None; single-use only.

- Replacement:

- Discard after each surgery.

- Cost per set: $10 – $50.

3. Electrode Pads (Scalp or Skin Contact)

- Use:

- Attach to the skin using adhesive backing.

- Ensure proper placement to minimize signal loss.

- Maintenance:

- None; disposable and single-use.

- Replacement:

- Replace after each use.

- Cost per set: $10 – $30.

4. Conductive Gel and Paste

- Use:

- Apply directly to the skin before attaching electrodes.

- Spread evenly to ensure good electrical conductivity.

- Maintenance:

- Store in a cool, dry place with the cap tightly sealed.

- Replacement:

- Replace after each patient use.

- Cost per tube: $5 – $15.

5. Disposable Stimulation Probes (If Used)

- Use:

- Apply sterile stimulation probes to nerve locations during stimulation tests.

- Ensure precise placement for effective nerve response monitoring.

- Maintenance:

- None; single-use only.

- Replacement:

- Discard after each procedure.

- Cost per probe: $50 – $200.

6. Connecting Cables (Limited-Use)

- Use:

- Connect electrodes to the amplifier and processing unit.

- Ensure proper connection points to prevent signal disruption.

- Maintenance:

- Clean cables with alcohol wipes after each use.

- Inspect for wear, fraying, or loss of insulation.

- Replacement:

- Replace when damaged or signal integrity is compromised.

- Cost per cable: $20 – $100.

7. Sterile Drapes & Covers (Protective Use)

- Use:

- Cover non-sterile components to maintain a sterile field.

- Protect electrodes and cables from contamination.

- Maintenance:

- None; single-use only.

- Replacement:

- Discard after each procedure.

- Cost per drape or cover: $5 – $15.

Comparison with Brand A & Brand B IONM Systems

| Aspect | Bioscope by Biosys | Brand A | Brand B |

| Needle Electrodes | Single-use, disposable. | Single-use, disposable. | Single-use, disposable. |

| Adhesive Electrodes | Single-use, disposable. | Single-use, disposable. | Single-use, disposable. |

| Electrode Pads | Single-use, disposable. | Reusable types available for EEG. | Reusable and single-use options. |

| Conductive Gel/Paste | Single-use per patient. | Single-use per patient. | Single-use per patient. |

| Stimulation Probes | Single-use, limited-use. | Reusable with sterilization. | Reusable and disposable options. |

| Connecting Cables | Reusable, limited lifespan. | Reusable, more durable. | Reusable, high-quality shielding. |

| Sterile Drapes & Covers | Single-use. | Single-use. | Single-use. |

| Cost Range (Per Use) | $100 – $300 per surgery. | $200 – $500 per surgery. | $250 – $600 per surgery. |

| Sterilization Needs | Limited to connecting cables and stimulation probes. | Extensive for probes and cables. | Extensive for probes, cables, and electrodes. |

| Maintenance Frequency | Low to moderate. | High (more parts requiring sterilization). | High (multi-modality systems). |

| System Focus | ENT & Peripheral Nerve Monitoring. | Cranial, Spinal, and ENT Monitoring. | Comprehensive, Multi-Modality Monitoring. |

The Bioscope by Biosys, designed for simplicity and cost-effectiveness, is ideal for ENT, hand, and facial surgeries due to its low maintenance and minimal consumable requirements. It provides essential monitoring, especially for laryngeal nerve function, making it a valuable tool in delicate nerve surgeries. Its ease of use and affordability make it a go-to option for institutions with limited resources.

Brand A offers multi-modality support, including EEG, EMG, MEP, and SSEP monitoring capabilities, making it versatile in a wide range of surgical procedures, from cranial to spinal surgeries. While it uses similar consumables to other systems, its complex nature demands more thorough sterilization and frequent maintenance. The system’s multi-modality capabilities make it invaluable in high-risk surgeries but also require more careful handling to ensure reliability and patient safety.

Brand B, a comprehensive and high-precision system, is the most resource-intensive of the three. It supports a wide variety of surgeries, including spinal and brain procedures, and requires frequent replacement of high-quality electrodes and probes. Its advanced features make it suitable for complex surgeries, but the broad application scope comes with the tradeoff of higher operational costs and greater maintenance needs.

Standard Operating Procedure (SOP) for Using, Maintaining, and Replacing Consumables in the Bioscope System

This SOP will help you ensure effective use, maintenance, and replacement of consumables for the Bioscope by Biosys neuromonitoring system. It also includes cost optimization strategies and efficiency improvements.

Section 1: Preparation & Setup

1.1 Preparation Before Surgery

- Check Inventory:

- Ensure sufficient supply of all required consumables:

- Needle Electrodes (EMG)

- Adhesive Surface Electrodes (EMG, SSEP)

- Electrode Pads

- Conductive Gel / Paste

- Disposable Stimulation Probes (if used)

- Connecting Cables (reusable)

- Sterile Drapes & Covers

- Ensure sufficient supply of all required consumables:

- Visual Inspection:

- Examine reusable components (cables, stimulation probes) for signs of damage, fraying, or corrosion.

- Replace damaged items immediately.

- Sterility Check:

- Confirm that all disposable items are sealed and sterile before use.

- Equipment Calibration:

- Test and calibrate the signal amplifier and data acquisition unit.

- Ensure all connections are secure and functional.

Section 2: Intraoperative Use

2.1 Setting Up Consumables

- Needle Electrodes (EMG):

- Insert into the muscle groups associated with the nerves being monitored.

- Secure using adhesive pads or clips as needed.

- Adhesive Surface Electrodes (EMG, SSEP):

- Apply a thin layer of conductive gel or paste to the skin before placement.

- Attach electrodes firmly and ensure proper contact.

- Electrode Pads:

- Apply directly to the skin where signal acquisition is needed (e.g., scalp or limbs).

- Stimulation Probes (If Used):

- Attach to the nerve sites for direct stimulation.

- Monitor response via the Bioscope interface for real-time feedback.

Section 3: Post-Surgery Cleanup & Maintenance

3.1 Consumable Replacement

- Single-Use Components:

- Discard all used needle electrodes, adhesive electrodes, electrode pads, stimulation probes, and drapes/covers in appropriate biohazard disposal containers.

- Limited-Use Components (Connecting Cables):

- Clean cables with alcohol wipes or disinfectant solutions.

- Inspect cables for physical damage before next use.

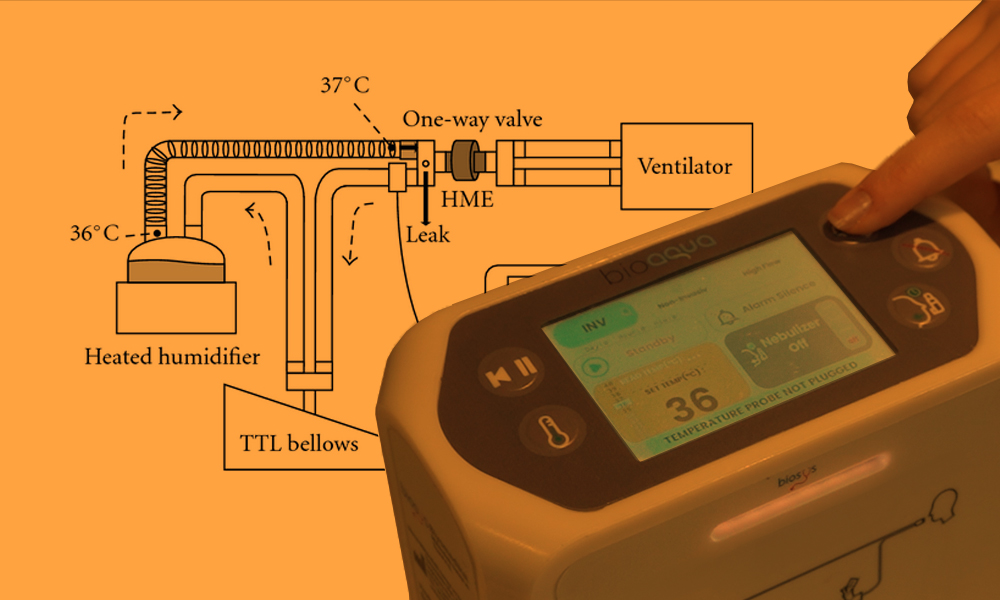

3.2 Sterilization of Reusable Components

- Connecting Cables & Stimulation Probes:

- Clean with 70% isopropyl alcohol wipes or appropriate disinfectants.

- For stimulation probes:

- If reusable, sterilize using an autoclave (if heat-tolerant) or chemical disinfectants (e.g., glutaraldehyde).

- Dry thoroughly before storing.

3.3 Data Backup & Software Maintenance

- Save patient data to secure storage systems as per medical standards.

- Check for software updates to maintain optimal performance.

- Run diagnostic tests to ensure proper calibration and system integrity.

Section 4: Cost Optimization & Efficiency Improvements

Strategies to Reduce Costs and Improve Efficiency

- Bulk Purchasing:

- Purchase needle electrodes, adhesive electrodes, and electrode pads in bulk to reduce per-unit costs.

- Using Reusable Components Where Safe:

- Invest in high-quality, reusable connecting cables and stimulation probes.

- Follow strict sterilization protocols to maximize lifespan.

- Maintenance Schedule:

- Implement a scheduled maintenance plan for reusable components to ensure reliability and reduce replacement frequency.

- Regular Supplier Evaluation:

- Compare suppliers for competitive pricing and quality.

- Negotiate contracts with manufacturers for long-term supply at reduced rates.

- Staff Training:

- Provide training on proper handling, cleaning, and disposal procedures to prevent damage and contamination.

Section 5: Comparison with Other Systems

| Aspect | Bioscope by Biosys | Brand A | Brand B |

| Single-Use Parts Cost | Lower (Approx. $100 – $300 per surgery) | Moderate (Approx. $200 – $500 per surgery) | High (Approx. $250 – $600 per surgery) |

| Sterilization Needs | Limited to cables and stimulation probes | Extensive; requires frequent sterilization of probes and cables. | Frequent sterilization needed for all components. |

| Reusable Components | Cables, Stimulation Probes (if used) | Cables, Probes, Certain Electrodes | Cables, Electrodes, Stimulation Devices |

| Maintenance Frequency | Moderate (Few components to sterilize) | High (Multiple components) | High (Multi-modality systems) |

| Cost Optimization Methods | Bulk purchasing and reusing cables where possible. | Long-term contracts with suppliers. | Careful maintenance and cleaning of reusable parts. |

| Component Lifespan | Moderate to High (Reusable components last longer with proper care). | Moderate (High maintenance cost). | High (Excellent durability but complex handling). |

Use of Neuromonitoring in ENT (Ear, Nose, Throat) Operations

Neuromonitoring is increasingly used in ENT surgeries to preserve nerve integrity and prevent nerve damage, especially when critical nerves are at risk of injury. Its use in ENT procedures is particularly important because even minor damage to nerves can cause significant functional impairments, such as voice loss, swallowing difficulties, or facial paralysis.

Common ENT Surgeries Where Neuromonitoring Is Used

1. Thyroid and Parathyroid Surgery (Most Common Use)

- Nerve at Risk: Recurrent Laryngeal Nerve (RLN) and Superior Laryngeal Nerve (SLN).

- Why Neuromonitoring is Important:

- The RLN controls the muscles of the vocal cords; injury can cause hoarseness, loss of voice, or breathing difficulties.

- The SLN affects voice pitch; injury can result in difficulty modulating voice.

- How Neuromonitoring is Used:

- Electrodes are placed on the vocal cord muscles (via endotracheal tube electrodes) or on the skin near the laryngeal muscles.

- Electrical stimulation is applied, and the EMG response is monitored in real-time.

- Visual and audio alerts indicate proximity to or damage of the nerve.

2. Parotid Gland Surgery (Facial Nerve Monitoring)

- Nerve at Risk: Facial Nerve (CN VII).

- Why Neuromonitoring is Important:

- The Facial Nerve controls muscle movements of the face.

- Injury can cause partial or complete facial paralysis.

- How Neuromonitoring is Used:

- Surface or needle electrodes are placed in facial muscles innervated by the facial nerve.

- Continuous EMG monitoring detects nerve activity during surgery.

- Alerts warn the surgeon when nerve manipulation is detected.

3. Skull Base Surgery (Cranial Nerve Monitoring)

- Nerves at Risk: Facial Nerve (CN VII), Vagus Nerve (CN X), Glossopharyngeal Nerve (CN IX).

- Why Neuromonitoring is Important:

- The nerves involved are essential for swallowing, speech, facial movements, and other critical functions.

- Damage can cause permanent deficits if not detected early.

- How Neuromonitoring is Used:

- Electrode placement around nerves at risk.

- Monitoring of muscle activity during surgical manipulation.

- Audio-visual feedback provided in real-time.

4. Cochlear Implant Surgery

- Nerve at Risk: Facial Nerve (CN VII).

- Why Neuromonitoring is Important:

- The facial nerve is very close to the surgical area when inserting cochlear implants.

- Prevents accidental damage during electrode array insertion.

- How Neuromonitoring is Used:

- Continuous monitoring of facial muscle activity to avoid nerve damage.

- EMG electrodes are placed over relevant muscles.

5. Ear Surgeries (e.g., Mastoidectomy)

- Nerve at Risk: Facial Nerve (CN VII).

- Why Neuromonitoring is Important:

- Injury to the facial nerve can result in facial droop or paralysis.

- Necessary during procedures involving the mastoid bone or middle ear.

- How Neuromonitoring is Used:

- Real-time monitoring of nerve function using EMG electrodes.

- Electrical stimulation can be applied to detect nerve presence.

How Neuromonitoring Works in ENT Surgeries (Bioscope Example)

- Placement of Electrodes:

- Needle or surface electrodes are placed on or near the muscles controlled by the nerves at risk (e.g., laryngeal muscles for RLN monitoring).

- Nerve Stimulation:

- Low-level electrical stimulation is applied near the surgical area.

- The nerve response is recorded by the electrodes.

- Signal Interpretation:

- The recorded signals are processed by the Bioscope system.

- Waveforms are displayed on the touchscreen and provide visual/audio alerts.

- Safety Alerts:

- When nerve damage or proximity is detected, the system provides immediate feedback to the surgical team.

Comparison with Other Neuromonitoring Systems

| System | Bioscope by Biosys | Brand A | Brand B |

| Primary Application | ENT (Thyroid, Parathyroid, Facial Surgeries) | ENT, Cranial, Spinal Surgeries | Comprehensive (ENT, Spinal, Brain Surgeries) |

| Nerves Monitored | RLN, SLN, Facial Nerve | Cranial & Spinal Nerves | Peripheral, Cranial & Spinal Nerves |

| Alert Systems | Visual & Audio Alerts | Visual & Audio Alerts | Visual & Audio Alerts |

| Display Type | 10.1-inch Touchscreen | Standard LED/Touchscreen | High-Resolution Display |

| Portability | Yes (Battery-Powered) | No | Yes (Limited) |

| Cost Efficiency | More Cost-Effective for ENT Applications | Moderate to High | High |

Benefits of Using Neuromonitoring in ENT (Ear, Nose, Throat) Surgeries

Neuromonitoring has become a critical tool in ENT surgeries, where preserving nerve function is essential to maintaining speech, facial movements, breathing, swallowing, and hearing. The implementation of neuromonitoring devices, such as the Bioscope by Biosys, provides significant benefits across various ENT procedures.

1. Enhanced Nerve Safety and Preservation

- ENT surgeries often involve high-risk nerves like the Recurrent Laryngeal Nerve (RLN), Superior Laryngeal Nerve (SLN), and Facial Nerve (CN VII).

- Real-time monitoring allows surgeons to detect and avoid damage to these nerves during procedures like:

- Thyroidectomy and Parathyroidectomy (RLN and SLN monitoring).

- Parotid Gland Surgery (Facial Nerve monitoring).

- Cochlear Implantation and Mastoidectomy (Facial Nerve monitoring).

- Prevents permanent functional loss, including:

- Hoarseness or voice loss (RLN injury).

- Pitch modulation difficulties (SLN injury).

- Facial paralysis or drooping (Facial Nerve injury).

2. Increased Surgical Precision

- Visual and Audio Feedback:

- Systems like Bioscope provide real-time visual displays and audio alerts when nerves are at risk.

- Surgeons can make precise adjustments instantly based on the feedback received.

- Better Identification of Nerve Structures:

- Improves detection of nerves that are difficult to visualize due to scar tissue, tumors, or anatomical variations.

- Enhances precision in tumor resections, parotidectomies, and complex ear surgeries.

3. Reduced Postoperative Complications

- Significantly reduces the risk of:

- Vocal cord paralysis during thyroid and parathyroid surgeries.

- Facial muscle dysfunction following parotid and skull base surgeries.

- Swallowing difficulties and airway compromise from nerve damage.

- Faster recovery times due to reduced nerve trauma and improved surgical technique.

4. Improved Surgical Outcomes

- Enhanced nerve preservation leads to better functional recovery and patient satisfaction.

- Reduced rates of reoperation due to nerve damage.

- Minimizes the risk of long-term disabilities associated with nerve injuries.

5. Early Detection of Nerve Stress or Injury

- Continuous monitoring during surgery helps identify early signs of nerve stress or dysfunction.

- Systems like Bioscope alert the surgeon before permanent damage occurs, allowing for immediate correction.

- Detection of near-miss injuries prevents complications that may only become evident postoperatively.

6. Cost-Efficiency in Preventing Complications

- By preventing nerve damage, neuromonitoring can save significant healthcare costs associated with:

- Prolonged hospital stays.

- Additional surgeries required to repair nerve damage.

- Long-term rehabilitation or therapy costs.

- Bioscope’s focus on ENT procedures provides a cost-effective solution specifically tailored for laryngeal and facial nerve monitoring.

7. Enhanced Training and Surgical Education

- Neuromonitoring systems provide visual aids and feedback that can be used for educational purposes.

- Surgeons in training can learn precise nerve identification and protection techniques with real-time guidance.

8. Better Patient Communication and Satisfaction

- The use of neuromonitoring can be explained to patients as a safety measure that enhances surgical precision and reduces risks.

- Improved patient confidence in the procedure knowing that measures are in place to protect critical nerves.

9. Minimally Invasive Surgery Compatibility

- Neuromonitoring systems like Bioscope can be integrated with minimally invasive surgical techniques, offering benefits such as:

- Smaller incisions.

- Reduced tissue trauma.

- Faster healing and recovery.

10. Integration with Other Surgical Technologies

- Neuromonitoring systems can work in tandem with:

- Surgical microscopes.

- Endoscopic instruments.

- Robotic-assisted surgical tools.

- Enhances the accuracy of delicate procedures where visualization alone is not sufficient.

Comparison of Benefits: Bioscope vs. Other Systems

| Benefit | Bioscope by Biosys | Brand A | Brand B |

| Real-Time Feedback | Visual & Audio Alerts | Visual & Audio Alerts | Visual & Audio Alerts |

| Cost Efficiency | High (ENT-Focused) | Moderate (Multi-Purpose) | Low (Comprehensive Monitoring) |

| Ease of Use | High (User-Friendly UI) | Moderate (More Complex Setup) | Moderate (Advanced System) |

| Portability | High (Battery-Powered) | Low (Stationary Systems) | Moderate (Limited Portability) |

| Best Applications | ENT Surgeries (RLN, SLN, Facial Nerve) | ENT, Spinal Surgeries | Comprehensive Nerve Monitoring |

| Customization Options | Limited (Dual-Channel) | High (Multi-Modality) | High (Multi-Modality) |